PAPERLESS REPORTING

Lifting and Mechanical

PAPERLESS REPORTING FOR INDUSTRY LIFTING & MECHANICAL

YOUR INSPECTIONS AND REPORTING MADE EASY

PAPERLESS REPORTINGLIFTING AND MECHANICAL INSPECTION MANAGEMENT

Key figures about Lifting and Mechanical Inspection Application:

- Cloud based paperless reporting system specifically designed for Oil & Gas Industry.

- Track Lifting and Mechanical inspections.

- Manageable dashboard that gives relevant and up-to-date KPI`s and information about the current Lifting inspection or client lifting equipment.

- Equipment location and detail info.

- Equipment certificate status.

- History of inspection points per equipment.

- Defects and defect history per equipment.

- One click report or lifting register generation.

Audit Log and Tracking system for every user action.

Access Levels and Authorizations & Privileges System:

The Lifting and Inspection management application is designed to offer four different types of access levels, which are pre-defined with a set of privileges and authorizations.

- IT Administrators – Unlimited access.

- Managers – Add clients, countries, installations.

- Inspectors – Add equipment, create reports.

- Clients – View only its own equipment, print reports.

State of the art tracking system of logged users, actions taken etc., for later review if needed.

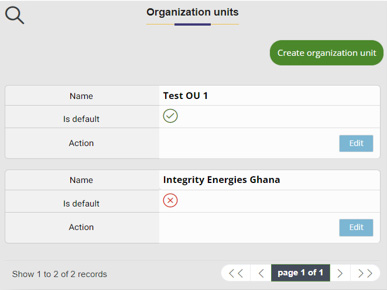

CLIENTS & ORGANIZATION UNITS:

Top level information. Each data is connected to the organization unit or the inspection body. Offering clients and equipment to related to this entity.

Complete client register with detail information for each client. Name and address details, contact points and email notification settings from the application system.

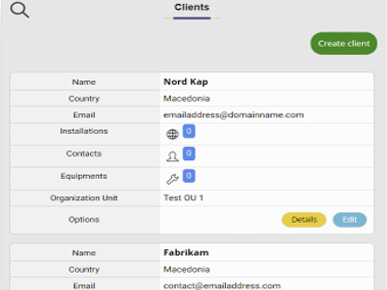

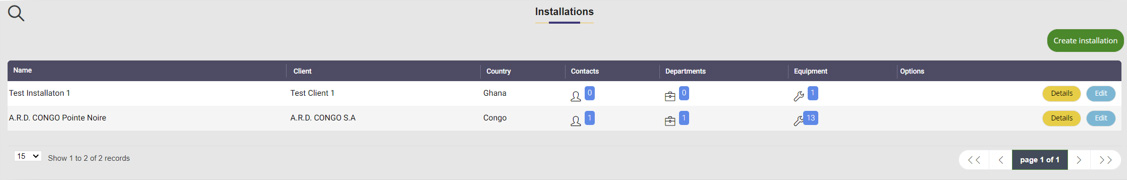

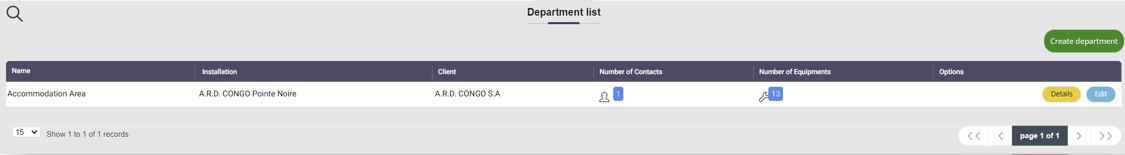

CLIENTS / INSTALATIONS & DEPARTMENTS:

List of installations per client. Detail information for each one with direct access to allocated equipment and inspection points.

List of installations per client. Detail information for each one with direct access to allocated equipment and inspection points.

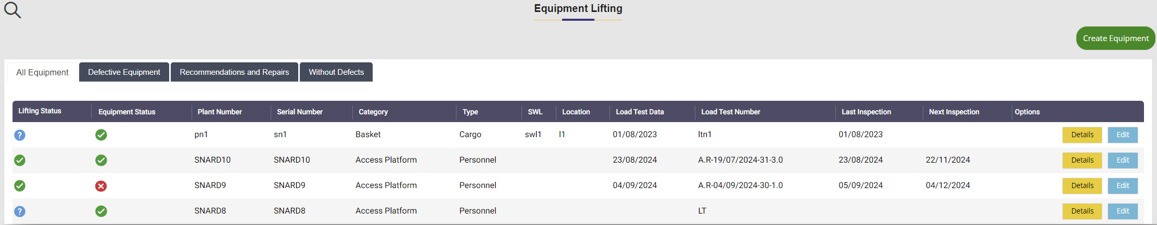

EQUIPMENT REGISTER

- Complete equipment register.

- Easy to navigate through all equipment, defective equipment, equipment which is identified with low or medium priority defects or even equipment which was never inspected.

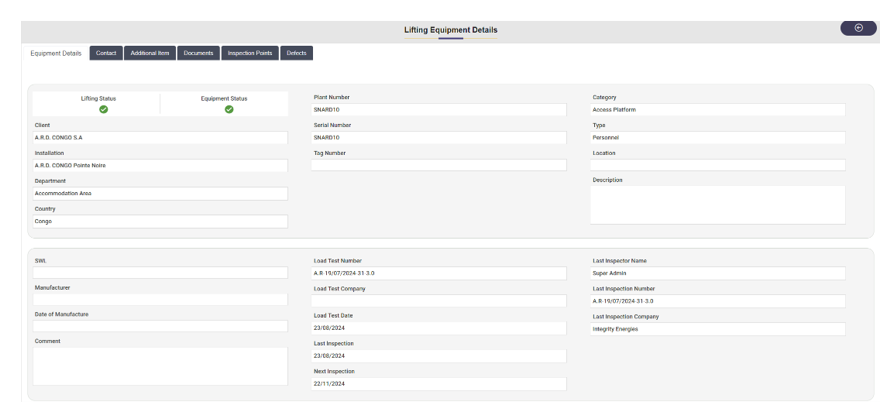

- All equipment data in one page.

- Quick status indication of the health of the equipment (Lifting status and Equipment Status).

- Access to view additional items connected to the specific equipment.

- Access to uploaded equipment documentation.

- Access to all inspections and inspection points carried out for the specific equipment.

EQUIPMENT PACKAGES:

- There is always a situation on the field when the inspection needs to be carried out on hundreds and sometimes thousands of similar pieces of equipment.With our built-in functionality of virtual equipment packages, inspectors can:

- Allocate unlimited amount of equipment in single virtual equipment package.

- Create inspection point and Lifting Visual Certificate or Lifting Test Certificate only once on the level of the equipment package.

- The system will automatically produce the same inspection report (with the data of each equipment separately). Thus, saving significant amount of time for the inspectors on the field.

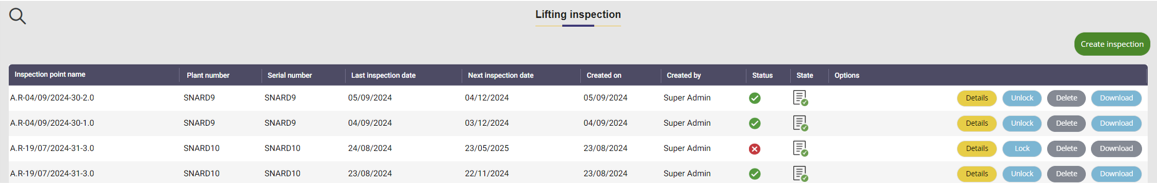

INSPECTION POINTS AND INSPECTION MANAGEMENT:

- The inspection points module allows the inspectors and clients complete view of all inspection done for the complete equipment register. With detail information like:

- For which equipment, the inspection point is related.

- Inspection date and the validity of the certificate generated inside the inspection point.

- The responsible person (inspector name and surname which has carried out the inspection of the equipment).

- Status of the inspection point (completed / approved / not completed).

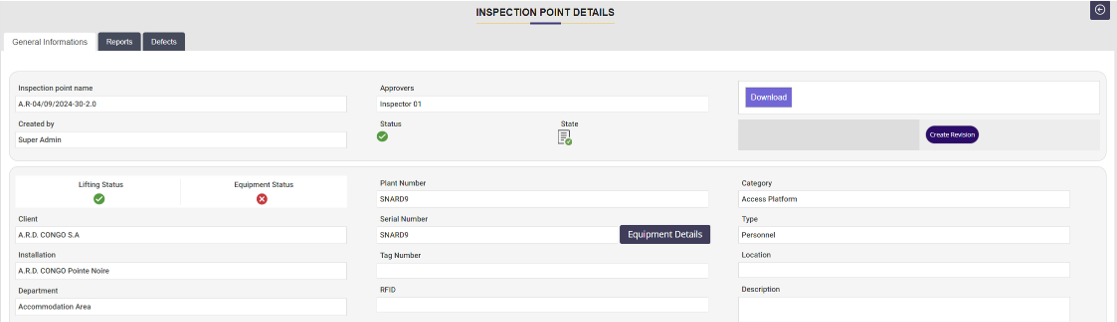

INSPECTION POINT DETAILS:

All the inspection details in one place.

- General information for the inspection point (equipment details, date of inspection, name of the inspector and the supervisor etc.).

- Number of reports generated in the specific inspection point (primary and secondary lifting checklists).

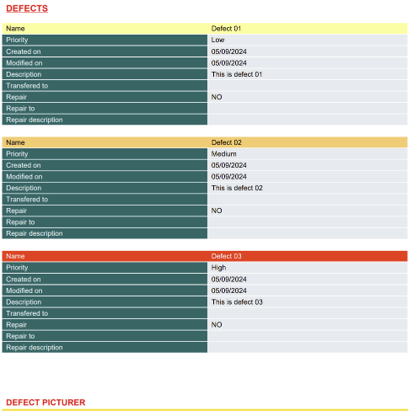

- Identified defects on the lifting equipment with severity of Low, Medium and High.

INSPECTION REPORT TYPES:

- All used lifting reports are already integrated in the application.

- Creating reports are as easy as filling few input fields, because all other are automatically populated.

- Clients can be automatically notified, by email, when defect has been recorded by the inspectors’ report.

Primary Reports

The Lifting and Mechanical inspection application includes the following primary certificate inspection templates:

- Lifting Visual Certificate (LVC)

- Load Test Certificate (LTC)

- Lifting Crane Certificate (LCC)

- Lifting Runway Beam Certificate (LRB)

Secondary (Checklist) Reports

The Lifting and Mechanical inspection application includes the following checklist certificate inspection templates:

-

- Forklift Checklist

- Articulating Boom Crane Checklist

- Vehicle Lift Checklist

- Rough Terrain Extended Reach Forklift Checklist

- Telescopic Boom Crane Checklist

- Overhead Crane Checklist

- Pedestal Crane Checklist

- Magnetic Particle Inspection

- Dye Penetrant Inspection

- Blank Inspection Checklist

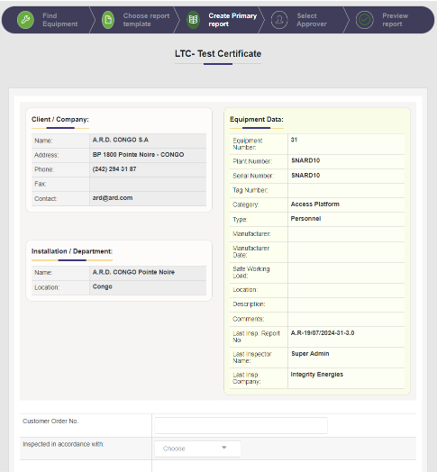

INSPECTION POINT / REPORT GENERATION:

It is where the actual equipment inspection is being done from the inspector side. Our application makes this process as easy as just following the simple wizard like process and the possibility of making error is at minimum level.

Each inspection is done in just a few easy steps:

-

- Find the equipment and create inspection point or create blank inspection point and allocate equipment.

- Choose a report template (primary or secondary checklist).

- Populate the report template form and allocate inspector supervisor for report approval.

- Preview and when finished complete the inspection point.

INSPECTION POINT / FINAL REPORT CERTIFICATE:

Complete inspection point in one PDF. Primary certificate, Lifting checklist, Defects and Pictures of the actual inspection on field.

CLIENT ACCESS:

The paperless reporting functionality will never be possible and complete without a dedicated client access in the Lifting and Mechanical Inspection Application.

Client is provided with access credentials and able to access the system in an isolated mode which allows him to see only the equipment and inspection data which are related to the specific client.

- The Client can easily print off any reports that has been created by the Inspector.

- Also, it is possible to view the equipment history, by printing all created reports at once.

- The possibility to print a whole lifting register or a separate category and type of equipment is also available with “one click”.

- If the Client prefers automated notification by emails the application can automatically send email with notifications about equipment which certificate is expired.

- Also, the Clients can be automatically notified, by email, when defect has been recorded by the inspectors’ report